Site Visit to Shettleston Geothermal System

Author: Alex Schlicke

On Tuesday 3rd November, members of the Hartwood Minewater Geothermal Energy feasibility study project team visited the operational geothermal system at 23 Glenalmond Street, Shettleston.

Shettleston Housing Association Property Manager, Ron Tracey, generously shared his time to explain to the team with the background to the scheme, the issues with its maintenance and operation, and to provide access to the energy centre.

The scheme was developed in 1999, with John Gilbert Architects leading on design. It is a 14 house development comprising a mix of terraced housing and flats in shared tenure. As a purpose built development, the buildings incorporated high levels of insulation, as well as other environmentally progressive measures, including solar water panels, solar air ventilation, water recycling and a vehicle free development.

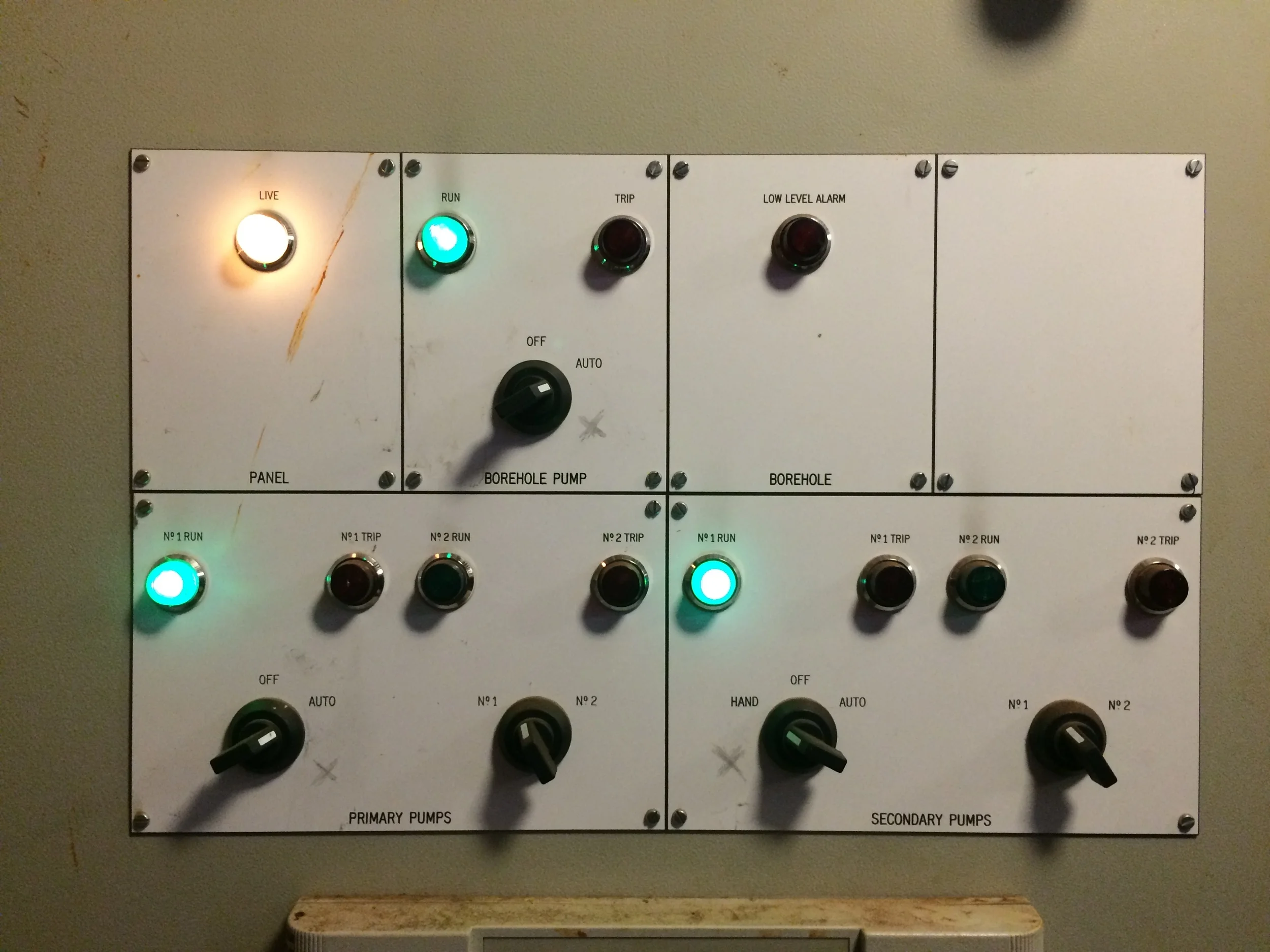

The minewater is pumped in an open loop system from a depth of ~80m, which then passes through a heat exchanger to provide the heat for the heat network for the development. In basic terms, the mine water is pumped up from the production well (at a temperature of ~12 degrees), enters the evaporator and there is a heat transfer between the mine water and refrigerant fluid (which vaporises) within the evaporator. After the heat transfer, the now cooled mine water flows to the injection well (at a temperature of ~7 degrees). The compressor uses electrical input to increase the pressure of the refrigerant vapour which consequently increases its temperature. Clean water enters the condenser and heat is transferred from the hot vaporised refrigerant. This heated clean water is stored in a very large storage tank, which contains immersion heaters that boost the temperature of the water supply from the heat pump from 55 to 65 degrees. This water is circulated to tenants. Ron opened up the heat exchanger to show the constituent parts, within a unit equivalent in size to a domestic boiler.

At the time of the site visit, the electric pool-pump back-up system was being replaced with gas boilers. The Housing Association were also installing heat meters in the individual properties. Up to this point the heating was supplied at a fixed rate, which at around £160 / year is a fraction of the £660 Scottish Household average. Billing was integrated with rent in one system.

This approach, while relatively simple for the Housing Association to manage, has disbenefits in terms of not providing any incentives for residents to conserve energy. A recent research paper from Changeworks presents the experience of social landlords of district heating, which is worth reviewing when considering the logistics of how the heat network near Hartwood could operate, including potential approaches to billing.

Ron talked about how the system had been trouble-free for the first ten years of its operation, but also acknowledged that in this period it had generally been free of any maintenance. At around year 10, the first pump needed to be replaced. Subsequently the Housing Association has developed a more pro-active maintenance regime, which includes regular maintenance of pumps on a 6 monthly basis, and periodic flushing to prevent build-up of iron deposits.

The system has been reliable and has provided very cost effective heat to tenants, but as a pioneering project, it faces particular issues when the system does not work. Ron highlighted the difficulties and delays in relation to the requirement for specialist maintenance. However, many of these issues can be satisfactorily resolved through the new gas back-up system, which will ensure continuous heat supply for residents during scheduled - and unscheduled - maintenance of the minewater geothermal system.

The team extends its thanks to Ron for sharing his time and knowledge in showing us around.

South facing flats at end and terraced housing on right

A manhole cover is the only marker for the location of the production well

Inner workings of the heat exchanger, showing the evaporator for the heat exchange (bronze); electrical compressor (blue), and condensor (black)

Ferrous build-up in pipework after ten years. Periodic flushing is now undertaken to maintain flow rates

Insulated pipework for the heat network, with the newly installed gas boiler backup system